Difference in Motor Performances 2: Life / Heat / Vibration etc.

More Difference in Motor Performances: Qualities and Additional Values

|

Last time, we discussed the motor elements such as (1) Rotation Speed (Speed), (2) Torque, (3) Size, and (4) Price. Matching these elements with your application will be the minimum requirement for using a motor. In other words, if you select the elements incorrect, the motor will not work as intended. The other elements to be discussed this time is the quality and added value of the motor. Depending on the application, it may be an element that you do not need to worry about, or it may be an important element that is absolutely essential. As mentioned above, there can be no excellent motor for everything including price. So, this time, we will clarify what kind of application the motor is used for, what kind of performance it has, and what kind of structure and ingenuity it consists of. The items we will discuss in this chapter are: Speed Accuracy / Smoothness / Life and Maintainability / Dust Generation / Efficiency / Heat Generation / Vibration and Noise / Countermeasure for Outgas / Operating Environment |

Smoothness and Accuracy of Revolution

When driving a motor at a stable speed, it will maintain a uniform speed according to inertia at high speeds, but it will make a difference at low speed according to the core shape of the motor.

In the case of a brushless motor with a slot, the attractive force between the slot teeth and the rotor magnets causes ripple at low speed. However, in the case of our brushless-slotless motors, because of the distance between the stator core and the magnet is constant in the circumferential direction (which means magnetic resistance is constant in the circumferential direction), ripple is unlikely to cause even at low speed.

Life, Maintainability, and Dust Generation

The most important elements in comparing brushed motors and brushless motors are life, maintainability, and dust generation. Since a brushed motor rotates with the brush and commutator in contact with each other, the contacting part is inevitably worn off by friction.

Therefore, it is necessary to replace the entire motor, and dust generation due to wear debris becomes a problem. As the name implies, brushless motors do not have brushes, and so they have better life, maintainability, and less dust generation than brushed motors.

Vibration and Noise

Brushed motors generate vibration and noise due to friction between the brush and commutator, but brushless motors do not. Brushless motors with slots generate vibration and noise due to cogging torque, but slotless motors and coreless motors do not.

The state in which the rotation axis of the rotor and the center of gravity are off-center is called unbalance. When a rotor with an unbalance is rotated, vibration and noise will be generated, and they will increase as the motor speed increase.

Efficiency and Heat Generation

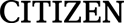

The ratio of the output mechanical energy against the input electrical energy is the efficiency of the motor. Most of the losses that did not become mechanical energy become thermal energy, and they will make the motor to generate heat. Motor losses include:

- Copper Loss (power loss due to electrical resistance of the winding)

- Iron Loss (stator core hysteresis loss, eddy current loss)

- Mechanical Loss (loss due to frictional resistance of bearings and brushes, and loss due

to air resistance: windage loss).

Copper loss can be reduced by reducing the winding resistance by thickening the magnet wire. However, if the magnet wire is made thicker, it would be difficult for the winding to fit in the motor. Therefore, it is necessary to design a winding structure that fits into the motor by increasing the space factor (ratio of conductor to cross-sectional area of winding).

If the frequency of the rotating magnetic field is high, the iron loss will increase, which means a motor with a high rotation speed will generate a large amount of heat according to the iron loss. Among the iron loss, the eddy current loss can be reduced by thinning the laminated steel sheet.

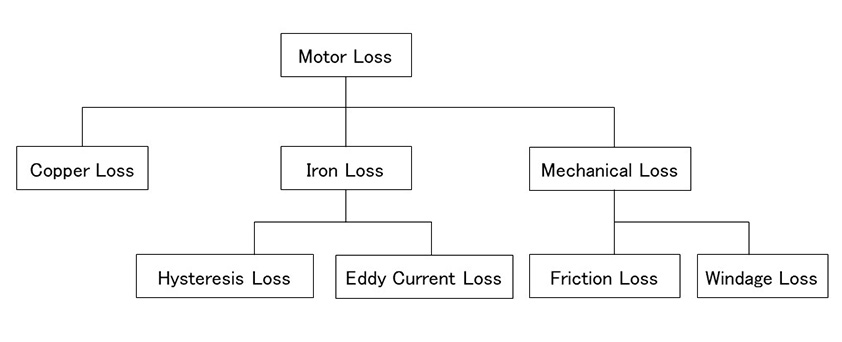

Regarding mechanical loss, brushed motors always suffer from mechanical loss due to the friction resistance between the brush and commutator, but brushless motors do not. Regarding bearings, ball bearings have lower friction coefficient than slide bearings, which improves motor efficiency. We use ball bearings for our motors.

The problem among heat generation is that even though an application has no restriction on the heat itself, the heat generated by the motor reduces its performance.

When the winding becomes hot, the electric resistance (impedance) increases and make difficult for current to flow, and as a result, it makes the torque to decrease. And also, when the motor becomes hot, the magnetic force of the magnet decreases due to thermal demagnetization. Therefore, heat generation cannot be ignored.

Because thermal demagnetization of magnet due to heat generation is smaller in samarium-cobalt magnet than in neodymium magnet, samarium-cobalt magnet is selected for application with high motor temperature.

<CITIZEN CHIBA PRECISION's Brushless Motor>

For Special Operating Environment

Positioning motors are used in semiconductor lithography system and FPD (Flat Panel Display) lithography system. The problem among exposure process is that optical components become cloudy by the outgas (gas) which is generated when photoresist is irradiated with light. Therefore, photoresist that generate less outgas is required.

Consequently, positioning motors are also required to have low outgas, and our low outgas motor bearings are made of fluorogrease, lead wire insulators are made of fluororesin, and adhesives are made of low outgas compatible products.

Motors used in clean rooms are required to have low dust generation. Brushless motors are often used because brushed motors generate wear debris. If you need a motor that generates less chemical pollutants, we can offer brushless motors with chemical countermeasures made from highly qualified materials.