Driver for Galvanometer Optical Scanner

Driver for Galvanometer Optical Scanner

|

Driver is the device which receives various feedback signals from the position detector and supplies power to control the mirror position (angle). It calculates the command signal to supply the power by comparing position command signal and position detector signal. The device which outputs the position command signal as mentioned above is controller. The controller commands the driver to position the mirror according to the purpose, and the driver controls the galvanometer scanner to follow this mirror position command signal. |

Models

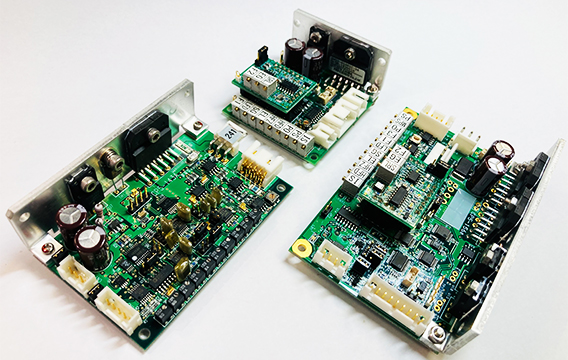

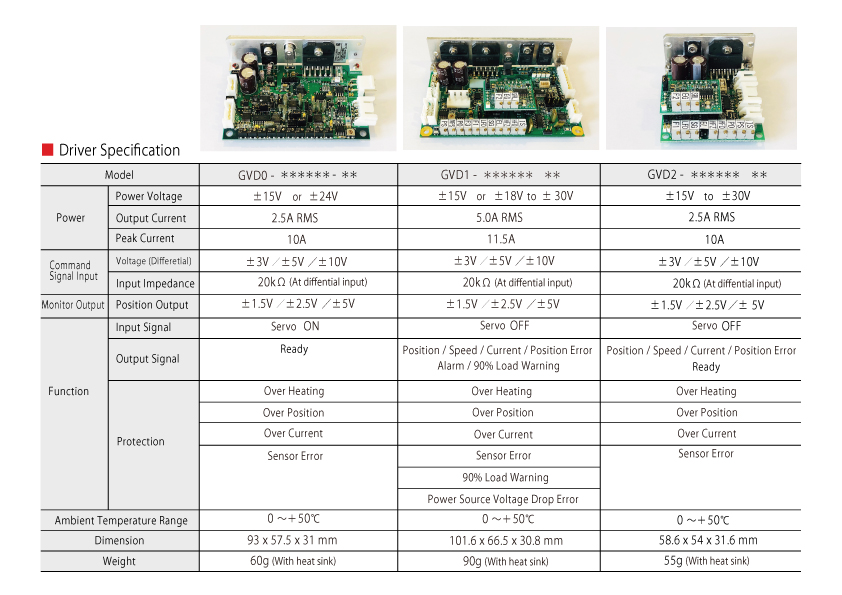

Citizen Chiba Precision has three types of drivers available for our galvanometer scanners:

- GVD0 for general-purpose

- GVD1 for high power-purpose

- GVD2 for small scanners (0930S / 0930L, 1445S / 1445L)

They are different in performance, size, and optimal application especially GVD2 is miniaturized by limiting the use to small scanners.

Their biggest difference is the instantaneous maximum current (peak current). The scanner generates acceleration (torque) proportional to the flowing. The larger the size in mirror inertia and acceleration, the larger current is required to obtain more torque.

Power Source Voltage

The DC power source must be used to the driver. Since optimal power source voltage differs depending on the model, please select ± 15V or ± 24V. Please note that ± dual power sources are required. Since the larger the power source voltage, the more advantageous for driving. ± 24V can perform higher than ± 15V.

GVD1 and GVD2 can also use different power source voltages. GVD1 can use ± 18V to ± 30V, and GVD2 can use ± 15V to ± 30V.

When selecting the capacity of the DC power source to be used, it is important to secure sufficient current. The item to be considered at the time of selecting is the maximum operating current, which requires 2.5A for GVD0 and GVD2 and 5A for GVD1.

Control System

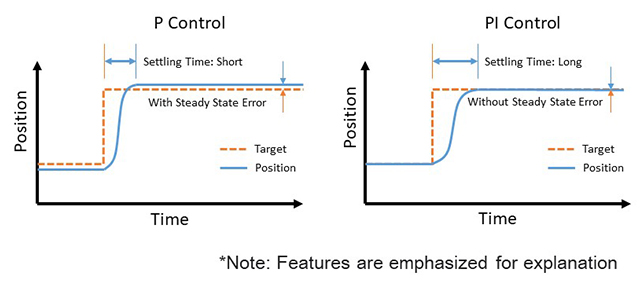

All of our drivers have two control methods called P Control and PI Control and please chose one according to the application. P Control focuses response speed, and PI Control focuses position reproducibility.

P Control compares the command signal and the position feedback signal for a proportional calculation. It operates at high speed but its position reproducibility is inferior for it does not have a means to correct steady position deviations.

PI Control calculates time integration (Integral) in addition to P Control. High position reproducibility can be obtained because the steady position deviation is integrated and corrected. However, because it requires integration time, it is inferior to P Control in speed.

Command Voltage

The maximum value of the command voltage can be changed. The standard is ± 10V, and when each of the positive and negative is 10V, it selects the maximum scan angle. It is determined according to the specifications of the command signal output from the controller.

Scan Angle

Please determine how much angle the galvanometer scanner oscillate to scan (mechanical angle). When the command voltage is in the maximum value, the scan angle set here will be used. Please do not set the angle beyond the specifications of the scanner.

Scanner Types and Laser Beam Diameter (Mirror Size)

The driver is optimally tuned for the size of the galvanometer scanner and mirror. Therefore, the superior performance cannot be achieved when different scanners and mirrors are combined. In some cases, it may oscillate wrongly and cause a malfunction. Therefore, please do not connect with any combination other than the one you ordered.

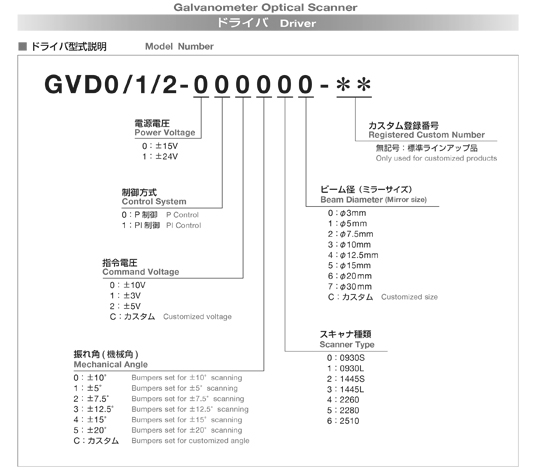

Model Number

Now you can select the model from these consideration items above.

The model cannot be selected unless the mirror and scanner are selected. And also, it is necessary to select the specifications according to the environment in which the galvanometer scanner is used, the power source of the device, and the specifications of the controller.