Mirror for Galvanometer Optical Scanner

Mirror for Galvanometer Optical Scanner

|

Mirror is the item which reflects the laser beams. The components to be considered in particular are size and coating, and both of them are selected according to the laser specifications. The size of the mirror is selected according to the size of the laser beam (diameter of laser beam) and the coating is selected according to the wavelength of the laser beam. |

Size of the Mirror

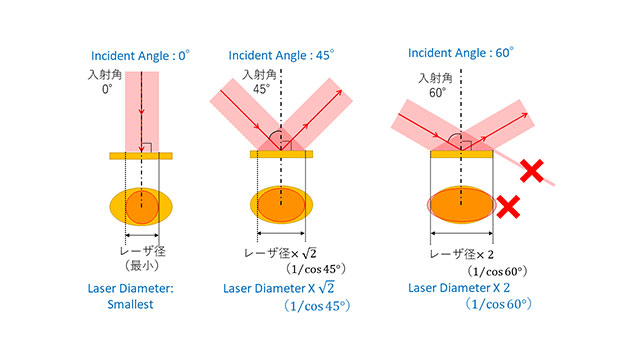

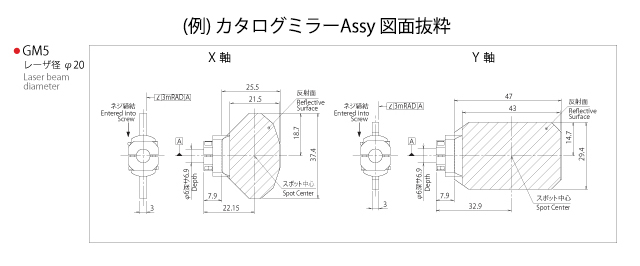

Our nominal mirror size is assumed to be in an incident angle of 45°. The diameter of laser beam becomes minimum when the incident angle is 0°. As the incident angle increases, the laser irradiation shape expands into an ellipse.

With our standard specification, we design our mirror to drive up to ±10°(mechanical angle) centered on an incident angle of 45 °. If more than 55°incident angle is expected, the laser beam will run over unless a larger mirror is used.

Of course, the moment of inertia will increase because the larger the mirror, the heavier it becomes. Therefore, large acceleration torque is required and this makes the current large.

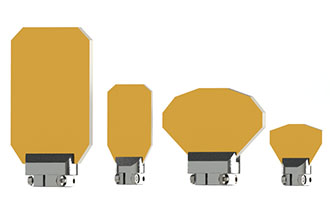

We provide the mirrors which laser diameters are in φ3/ 5/ 7.5/ 10/ 15/ 20/ 30 mm as our standard products. However, it is possible to mount a mirror which is customized to meet a customer’s required specification, or a customer-supplied mirror. Please contact us for more details.

Motor will be selected according to the size of the mirror. A small motor is suitable to drive a small mirror, and a large motor is suitable to drive a large mirror. Since mechanical characteristic is deeply involved with the size and the shape of the mirror, the driver also needs a custom tuning.

Shape of the Mirror

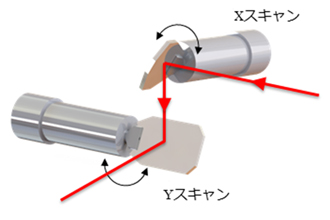

There are horizontally long mirror and vertical long mirror which are called as X-axis mirror and Y-axis mirror. When driving a laser beam in two dimensions of X-axis and Y-axis by combination of two scanners, the laser beam moved by X-axis mirror is moved on the Y-axis and this is why Y-axis mirror needs to be vertically long.

The X-axis mirror is sometimes called as Primary Mirror and Y-axis as Secondary Mirror. Primary means that laser beam reflects at first and secondary means that laser beam reflects at second. To make mechanical characteristics the same, we sometimes use Y-axis mirrors for both X and Y axes.

Substrate of Coating and Base Material

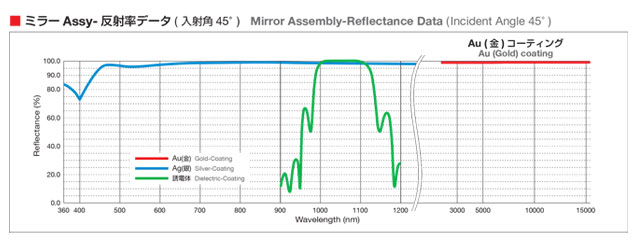

The mirror cannot reflect 100% of the light and the unreflected light is absorbed by the mirror to become heat. The degree of reflection depends on the characteristics of the coating, and each coating has a different reflectance and wavelength easily reflected. Therefore, it is necessary to select the coating according to the wavelength of the laser beam.

It is especially important for applications that use the energy of laser beam, such as laser processing machines. The amount of laser beam absorbed by the mirror is a loss, and if the mirror receives a large amount of energy, it may be damaged by heat generation. In some cases, heat generation cannot be ignored even at wavelengths that reflect the light well, and it may be necessary to use a larger mirror according to the laser diameter.

If you need to check the durability of the mirror, please let us know the wavelength, wattage, and irradiation time of the laser. We will check for you.

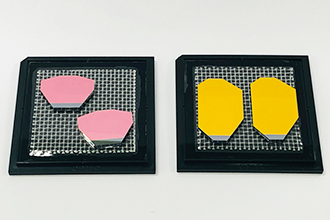

We have three kinds of coatings:

- Gold for CO2 Laser(Wavelength: 10.6 μm)

- Silver for Visible Ray Laser(Wavelength: 532nm / 1064nm etc.)

- Dielectric Multilayer for YAG Laser at Maximum Reflectance (Wavelength: 1064nm etc.)

Please note that in some cases, they are not valid according to the mirror sizes.

The Dielectric Multilayer Coating can be customized to reflect a specific wavelength, and we have experiences of proposing suitable ones for UV lasers. Please contact us for more details.

And also, there are two types of mirror base material. However, Si (silicon) is used for Gold and Silver Coatings, and SiO2 (synthetic quartz) is used for Dielectric Multilayer Coating.

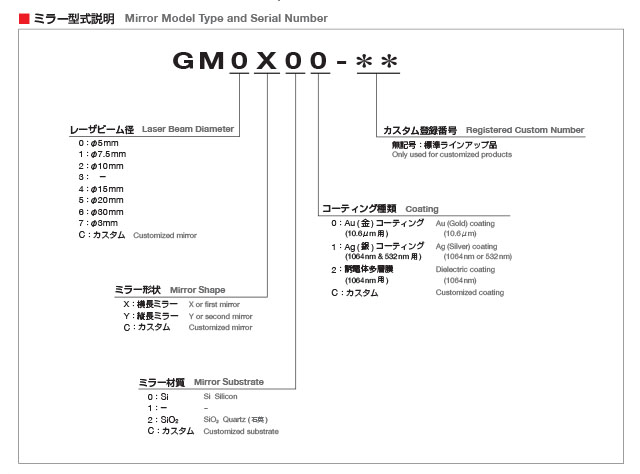

Model Number

For mirror base materials, Si and SiO2 are available as standard, which are selected by the mirror size and coating type. We can customize the mirror by materials other than these standard ones. Please contact our sales representatives or authorized distributors for more details.

Now you can decide the model by selecting the laser diameter, mirror shape, material, and coating from the list.